Ukuba umtsha kwi-levator yethu ye-Z, kuya kufuneka ubhideke ukuba usifaka njani isixhobo esikhulu emva kokuba usifumene.Ungakhathazeki, okokuqala, siya kuhlala sinawe ukukukhokela ukuba uyifake njani;okwesibini, nazi ezinye ii-ides zokwabelana nawe ukufaka i-elevator yebhakethi ngokukhawuleza.

1.Khangela ukuba ubungakanani benxalenye nganye ye-chassis buhambelana nobude bezixhobo ezithengiweyo ukugqiba indawo yofakelo lwamacandelo ahlukeneyo.

2.Hlola iindawo ezahlukeneyo zebhokisi ye-sprocket rotation iguquguqukayo ukuqinisekisa ukuguquguquka kokujikeleza kwe-sprocket ngaphandle kokuchasana.Kwi-sprocket esebenzayo, ngenxa yokunciphisa ukudibanisa kufuneka ukhulule i-torque limiter kwi-bolt ngoko inokujikelezwa.

3.Ngaphambi kokufakela, qiniseka ukuba isiseko sinamandla ngokwaneleyo kwaye umhlaba ulula.Ukuba kukho indawo engalinganiyo, nceda ulungise ubude beendawo ezahlukeneyo ngeenyawo ezilungelelanisiweyo ezisezantsi ukuqinisekisa ukuba ibhokisi ikwimo ethe tye.

4.Emva kokuba ukufakwa kwebhokisi kugqityiwe, nceda uhlolisise ukutyhutyha kwayo yonke into, ukuba ichanekile ke jonga ukuba indawo yezixhobo ezifanelekileyo ichanekile, ukuba ayilunganga indawo nceda ulungise, ukuba akukho ngxaki kwaye emva koko inyathelo elilandelayo.

5.Abahambisi abanobude obuphakamileyo okanye ubude obude, kuyafuneka ukuzinzisa ibhokisi kwindawo efanelekileyo kunye nesakhiwo esikufutshane, isakhiwo sentsimbi okanye isibiyeli esikhethiweyo se-welding ukuqinisekisa ukuba umthumeli unozinzo oluhle, akanako ukugubha , Swing kunye njalo njalo.

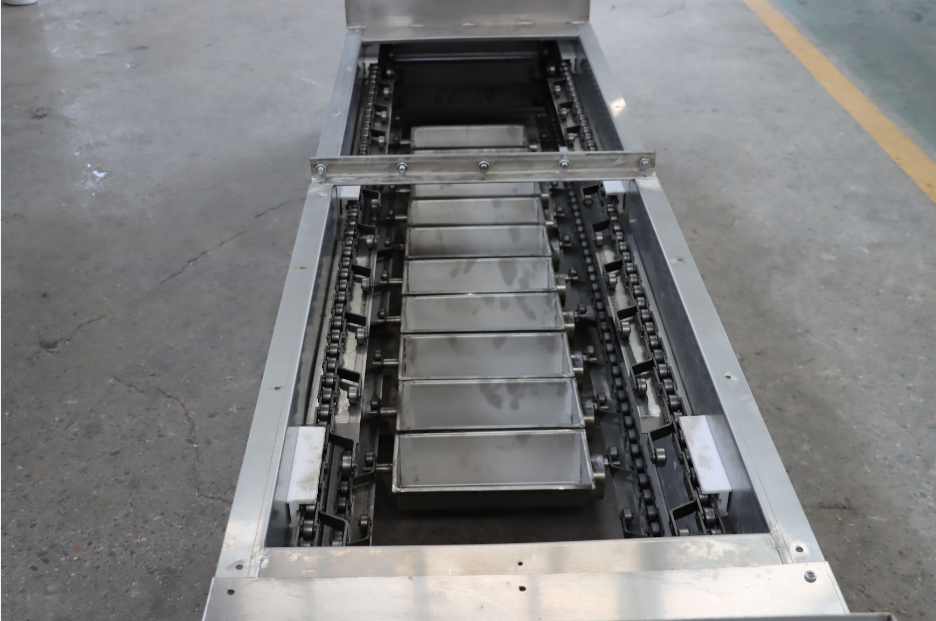

6.Xa uqala ukufaka ikhonkco, okokuqala faka i-elastic tensioner unscrew kwisithuba esifutshane kwaye uqinisekise ubude bekhonkco kunye nobude obufunekayo bufanayo.Ngomxokelelwane omfutshane wefektri yethu uya kuyidibanisa ngaphambi kokuthumela, kwikhonkco elide elifunekayo kwi-docking yasendle, indlela yokumisa iyafana nekhonkco eliqhelekileyo.Xa i-docking, qaphela ukuba isiphelo sesetyhula sekhonkco yomanyano sikwindlela efanayo kunye nolwalathiso oluqhubayo, kwaye isiphelo esivulekileyo sithintelwe ukuba singawi ngexesha lokusebenza.Ukuqinisekisa ukuba ubude bekhonkco kumacala omabini afanayo, ngokutsho kofakelo lofakelo lwe-conveyor, i-interface emva kwekhonkco iya kuqiniswa, ingabi nzima kakhulu, ilungele ukufakwa kwe-hopper.

7. Ngokuhambelana nolwalathiso lwekhonkco lokuhambisa ukufaka i-hopper ngokuchanekileyo, nikela ingqalelo inxalenye ye-hopper yokufakela isalathiso seempazamo zofakelo kuya kubangela umonakalo kwi-hopper, ukuba awuyazi ukufakela nceda uqhagamshelane ne-hopper. umenzi ukuqinisekisa.Kwimeko ye-chain chain , ikhonkco ukuya ngaphandle kwebhokisi ukuze ihlale, ikhonkco yekhonkco kunye ne-hopper kuzo zombini iziphelo zomngxuma ohambelanayo unokufakwa.Faka i-hopper kumgama omnye komnye kwaye ikhefu yi-127mm (2.0 litre lift).Chain turn, faka i-emele de lonke ufakelo oluchanekileyo lugqityiwe, ukufakwa kokuhambisa okufutshane kunokutshintsha ngesandla ikhonkco, ngenxa yesidingo eside sokudibanisa i-motor ukufaka i-hopper.

8.Emva kokuba i-hopper ifakwe ngokukhuselekileyo, i-spring tensioner inokuqinisa ikhonkco ukuqinisekisa ukuqina okufanelekileyo, kungekhona ukukhululeka okanye ukuqina.Qaphela ukuba ubude bamatyathanga amabini ahambelanayo, khangela ukuba i-axis ye-hopper kunye nebhokisi kwii-90 degrees, ezifana nobude bekhonkco bungahambelani, nceda uhlengahlengise kwakhona de ikhonkco kumacala omabini afane, kungenjalo kuya kuqhuba kakubi, isenzeko.

9.tshekisha zonke iindawo zeebholiti ukuba ziboshwe, ukuba zikhululekile nceda uqinise, uqinisekise ukuchaneka emva kwesinyathelo esilandelayo.

10.Khangela i-reducer kwioli yanele, ngokuqhelekileyo kwifektri yongezwe ukuba ioli ayanele nceda ungeze ioli eyaneleyo.Nika ingqalelo ekutshintsheni isiciko sesivalo seoyile sibe sisiciko esiphefumlayo ukuphepha ukonakalisa isinciphisi njengobushushu.

11.Qinisa umda wokuqinisa kwi-bolt esisigxina, vula umbane wamandla, isixhobo saqala ukusebenza singenanto.Kwisithuba seeyure ezi-2 umsebenzi wonke ugudileyo, i-hopper flip eqhelekileyo, khangela iibheringi, iimoto, i-reducers, (Ayikho ngaphezulu kwe-30 ℃), khangela ubude bekhonkco lomsebenzi, ukuba i-hopper iyaguquguquka, ukukhulula kucocekile, nokuba kukho okunye ukusilela, inokuba kukutya izinto eziyimfuneko.

Ixesha lokuposa: Nov-21-2022